How to Prepare your Data

Color

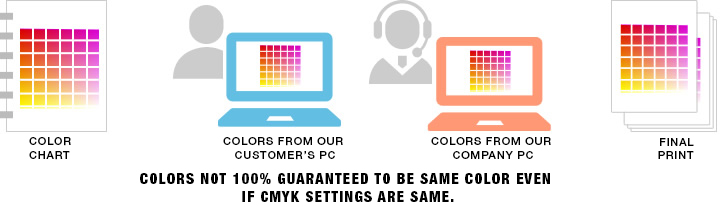

The color on the computer monitor and the color of the printed material are not necessarily the same.

Incomplete Data

Explain what kind data will be treated as "Incompleted Data". *Which means unable to proceed to production

File Formats

Explain types of file formats and Software that are supported for printing.

Resolutions

Explain the recommended resolution of images such as photos and other graphics.

Bleed

Explain what "bleed" is and why it is necessary for data with background color and images.

Safe Line

Explain about "Safe Line" and what happens during cutting process if you go over the line.

Fonts

Explains how to outline fonts when creating data with Adobe software.

Color Mode

Explain the color mode when creating with Adobe software.

Layer Effect

Explain the layer effect that may change the color when printing.

Re-Order Customers

Explain the color of the Reorder.

Accepted Applications & Formats

| Applications | Versions | Formats |

|---|---|---|

| Illustrator | 8~CC 2020 | ai・eps・pdfx1-a |

| Photoshop | 5.5~CC 2020 | eps・psd |

| Indesign | ~CC 2020 | indd・idd・pdfx1-a |

| Word | 2007~2019・Office365 | doc・docx・docm・dotx |

| Excel | 2007~2019・Office365 | xls・xslx・xltx・xlt |

| PowerPoint | 2007~2019・Office365 | ppt |

Please read the precautions when creating PDF data for submission in PDF format .

Please consult with us in advance if you wish to submit a data format (extension) that is not listed above.

Notes on creating data by application

Colors

Color difference on PC / Smartphone VS Printed materials

The coloring method for printing and the coloring method on the monitor are different. The screen of a PC or smartphone looks brighter than the printed material because the screen itself emits light. Also, because the color appearance changes depending on the monitor settings, the color when the print data is viewed on a computer or smartphone and the color of the finished print are not exactly the same.

Even with the same printer, the same paper and the same data, the color changes depending on weather conditions

Ink and paper are also affected by the temperature and humidity of the day, so even if you print with the same CMYK value and the same printing machine, it is impossible to “use 100% the same color”. Even if you reorder the same print data, the color will not be exactly the same as the previous time.

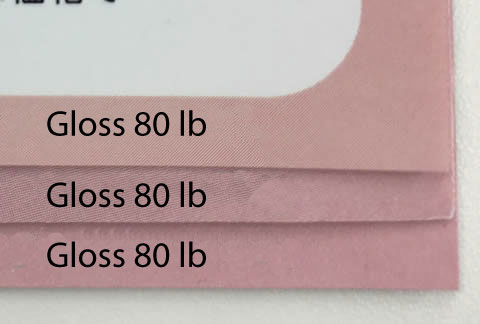

The same data is printed in three parts. Even in the same “C0% M30% Y14% K0%” pink, the concentration may vary depending on various factors such as the weather.

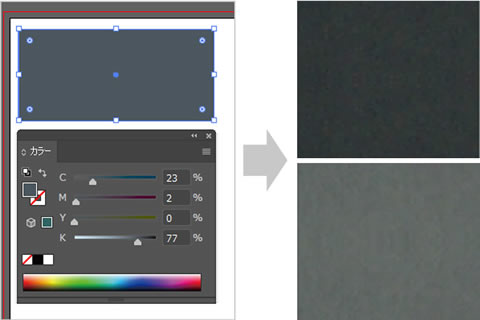

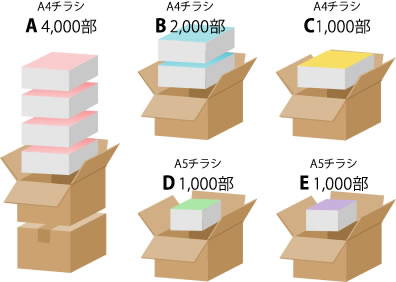

Colors that use all CMYK such as “C23% M2% Y0% K77%” are more likely to cause color blurring. The gray of the same CMKY value may differ by this amount.

Pale colors such as people's skin and clothing shadows are one of the areas where color differences tend to occur.

There is also a difference in the color of the middle part of the gradation.

To get the ideal color as close as possible, such as when you want to match colors or align colors with other printed materials, select the “Printer Color Matching” option and place an order.

In addition, blurring may be reduced by saying "Create data with only K1 color" for the gray part.

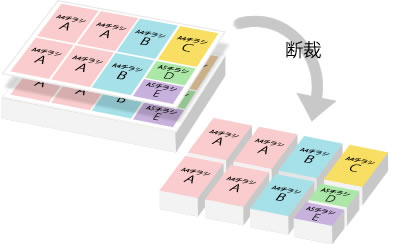

How to get the ideal color as close as possible?In order to make it low cost, we have introduced “Attach printing”.

“Attach printing” means imposing multiple customer data on a large sheet of paper and printing it simultaneously. This printing method can reduce costs and improve efficiency.

1.

For example ...

4,000 copies of A4 flyer

A4 flyer 2,000 copies

A4 flyer 1,000 copies

1,000 A5 leaflets

1,000 A5 leaflets

If you place an order for, print with imposition as shown on the right with a size of A1 or larger to create print data or plates.

2.

Print 1,000 copies of the created plate and cut it. with this,

4,000 copies of A4 flyer

A4 flyer 2,000 copies

A4 flyer 1,000 copies

1,000 A5 leaflets

1,000 A5 leaflets

Is completed.

3.

Each product is packed and dispatched to each destination.

In this way, since print data of multiple customers is printed at the same time, it is not possible to fine-tune the color according to specific data.

Pros and Cons of "Attach printing"

Pros: Multiple types of printed materials can be created with one edition, greatly reducing costs. It is possible to make printed materials at a low price.

Cons: Fine adjustments such as color are not possible, as with single printing.

How to get the ideal color as close as possible?

When ordering, please add this machine Color Matching option

Color proofing with "Printer Color Matching" is an option that allows us to start printing with a small number of copies before printing and after confirming the color, it will be proceeded to production. Orders without this color proofing option cannot be reprinted due to color differences.

To reduce color blurring… When creating data, create black and gray areas with one black color

All colors of printing are expressed by CMYK multiplication. Even in the same black, there are "Black using all CMYK" and "Black using only K", and if there is blurring in each ink, "Black using all CMYK" causes blurring for four colors, "Black using only K" is blurred for K 1 color only. For this reason, the black / gray area can be printed with less color blur when the data created with one black color is used. Colors that use all CMYK (dark blue, brown, engineering colors, etc.) will have an unstable finish.

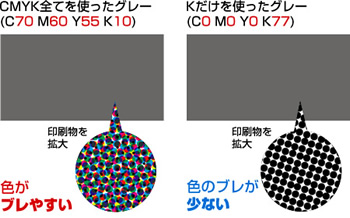

Data check / Incompleted data

If there are any incompletions in the submitted data, the customer would need to correct the data and resubmit. If re-submission is delayed, the delivery date will be delayed.

Flow from order to shipment

Examples of Incompleted that will lead to re-submit

In the following cases, correction and re-submission will be required so we will contact you. * If you "let us take care of it", we will proceed at our discretion.

- The number of colors at the time of ordering and the color of the submission data are different (eg, the submission data was color even though it was an order for one monochrome)

- Order contents and data size are different (Example: A4 order but trafficking data was B5)

- No Bleed

- Resolution is not appropriate

- Graphics are placed within 3mm from the finished line (graphics may be cut off)

- Layer integration (image integration) is not performed (Photoshop)

- The font is not outlined or embedded (in Illustrator)

- The image is not linked correctly (in Illustrator)

- No instructions for folding or drilling (when machining options are available)

- In the case of a perfect binding booklet, the back width is different from the order contents

- In the case of booklet binding, characters are placed 5mm from the throat side.

The following are not subject to data check

For the following, we will continue printing without checking our company.

- Sentence, character set, layout, design

- Typo, wrong URL

- Contents related to colors by overprinting

- Color mode (colors change because they are all decomposed into CMYK)

- Special color (All colors are disassembled into CMYK, so the color changes)

- Legacy text (may be garbled)

Orders WITHOUT color proofing "Printer Color Matching" CANNOT be reprinted due to color differences.

About Resolution

Please select an appropriate resolution according to your order

- Color 300-350dpi

- Grayscale 300-350dpi

- Monochrome 2 gradation 600-1200dpi

*Depending on the product, the resolution may be specified. Please carefully check the specifications and precautions of your order.

About Bleed

Include Bleed

Bleed is the portion of the printed background color or photo printed to the edge of the paper that is created 3mm or more above, below, left, or right over the finished size. For data with overcoat, the width and height are [finished size + 6mm] respectively.

When cutting, a large number of errors are inevitably generated because the majority are cut together. If there is no fill, the unprinted part will appear like a white border due to misalignment during cutting.

Data correction fee will be added separately if our company wishes to modify the coating. Click here for an example of correction costs In that case, please fill in the remarks column when you place an order.

*Depending on the data, we may not be able to correct it.

About missing characters

For characters and images that should not be cut, keep them 3mm or more away from the finished line.

When cutting, there will always be a slight shift in the cut-off position.

If the misalignment at the time of trimming is inward, if there is a character at the end of the finished position, it may be cut off.

Place characters that are in trouble if they are cut off when finished by placing them about 3 mm inward from the finished position.

Perform outline, image integration, and embedding according to the creation software.

If the text color is created with K100%, it will be displayed clearly when printed. (CMY10% or K100% is acceptable)

For Illustrator submission

Outline all character data. For details, see the precautions when creating Illustrator data.

For Photoshop submission

Perform “Merge Image” (when you merge images, all fonts become image data).

For details, see Notes on creating Photoshop data.

PDF submission

Embed all character data.

For details, please refer to the notes on creating PDF data.

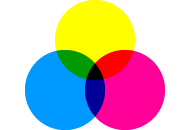

About Color Mode

The same color as the computer screen cannot be reproduced on paper

If you submit the document in RGB mode, we will convert it to CMYK mode and print it, but there will be a big difference in the finished color. In particular, light blue, pink, fluorescent, and dark amber colors change greatly. Reprinting due to color differences is not supported for orders without this machine's color proofing option.

Since the coloring method itself differs between the printed material and the computer screen, it is not possible to say “print the color displayed on the computer screen as it is”. Please see also about the color.

What is RGB color?

The RGB color is called the three primary colors of light and consists of three light sources: “Red”, “Green”, and “Blue”.

When these three lights are mixed, the color becomes brighter and approaches white, so it is said to be “additive color mixture”. The coloring method used on personal computers and smartphone screens, etc., makes the screen itself emit light and displays it, making it brighter and more vivid than printed materials.

What is CMYK color?

For CMYK colors, “K (Black)” is added to the three primary colors of “Cyan”, “Magenta”, and “Yellow”.

It is said to be “subtractive color mixing” because the color approaches black when mixed.

It becomes more and more cloudy gray, but it does not become “black”. Therefore, full color is expressed with 4 colors (process color) which added K (black) to CMY color.

Since it does not emit light like a PC / smartphone screen, even similar colors will appear darker than a PC / smartphone screen.

What happens when converting from RGB color to CMYK color

*Microsoft office software (word, excel, etc.) cannot be converted to CMYK, so it is also converted to CMYK when converting data at our company. As shown in the figure above, please note that the color changes greatly when RGB is converted to CMYK.

Do not use 4-color solids

4 colors solid = 4 colors (C / M / Y / K) 100%

It may cause trouble when printing.

If you want to increase the black depth, make the following settings.

Deep black = K100% + C100%

Deeper black (rich black) = K100% + C40% + M40% + Y40%

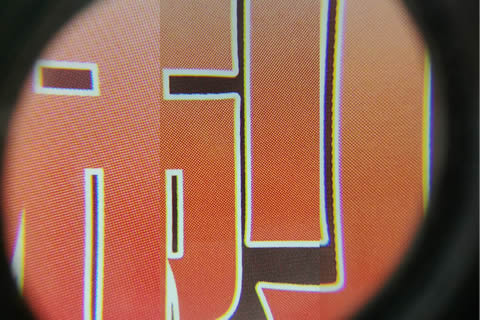

Notes on using Rich Black

*In the case of fine characters and thin lines, printing with rich black results in a slight misalignment during printing so that the color protrudes around the characters and lines.

"Black thin lines and letters on white background" , "White thin lines and letters on black background" When designing, be sure to create with K100% + C0% + M0% + Y0% without using deep black or rich black.

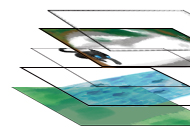

About Layer Effects

What is a layer effect?

This is a composite effect that can be set for each layer. By setting it, you can overlay colors on the layer below.

While allowing for a wide range of color representations, some layer effects are not applied when printed, and the result may not be as intended.

In particular, what is called the “translucent effect” shown below is not likely to be reflected, so caution is required.

List of effects that may not be reflected when printing

- Dodge

- Burn

- Comparison (dark)

- Comparison (light)

- Screen

- Soft light

- Hard light

*It ’s not something you should n’t use,

The finish may differ from the image!!

Remedy

By rasterizing each layer and integrating it into a single sheet without converting to PDF or uploading the original layer effect It can be closer to the finished image.